“His success will lead other people to create new art.” American resurgenceĪs Shapiro adjusted settings on a rose engine on a recent weekday, it drove home a point: This was a decidedly old-fashioned endeavor, applying centuries-old techniques to craft a wristwatch - itself something of an anachronism. “If he’s successful, he’d be sending up a bat signal to other watchmakers here that it’s OK to do this,” Rapkin said. The otherworldy timepieces sold out.Īsher Rapkin, co-founder of Collective, has been tracking Shapiro’s progress on his U.S.-made project. Released in 2020, the watches had dials made of meteorite and started at $21,500. Each featured the “infinity weave” - a guilloché pattern Shapiro invented - on the dial.Īmong those 100 watches were 10 that Shapiro made for Collective Horology, a Ventura company.

#Horology courses series

Shapiro and his colleagues eventually completed 100 of the Infinity Series watches, which used high-end movements made in Germany and sold for $30,000 on average. “I thought this would just be a hobby,” said the elder Shapiro, laughing. Keith Shapiro helped his son with the business in its early years - he once drove his son “almost all night” to Arizona so that the watchmaker could purchase that first guilloché machine. In 2017, he gave his dad a watch whose engine-turned dial he’d made. “Dealing with watch collectors is nothing dealing with teenagers and angry parents.”Īs Shapiro sharpened his skills, a few people close to him were the beneficiaries of his craftsmanship. Over roughly the next 10 years, Shapiro held various roles as an educator, including serving as a teacher and principal at a private Jewish high school in the Pico-Robertson area. By then, he’d already begun a career in education, having coached track and field and worked as a substitute teacher at Arcadia High School. He got a master’s degree in history at Cal State Northridge six years later. Shapiro pursued his love of history at UCLA, where he majored in the subject, graduating in 2008. Still, it was far from a straight path to watchmaking. “You can have a fulfilling, wonderful life doing things differently than other people.”

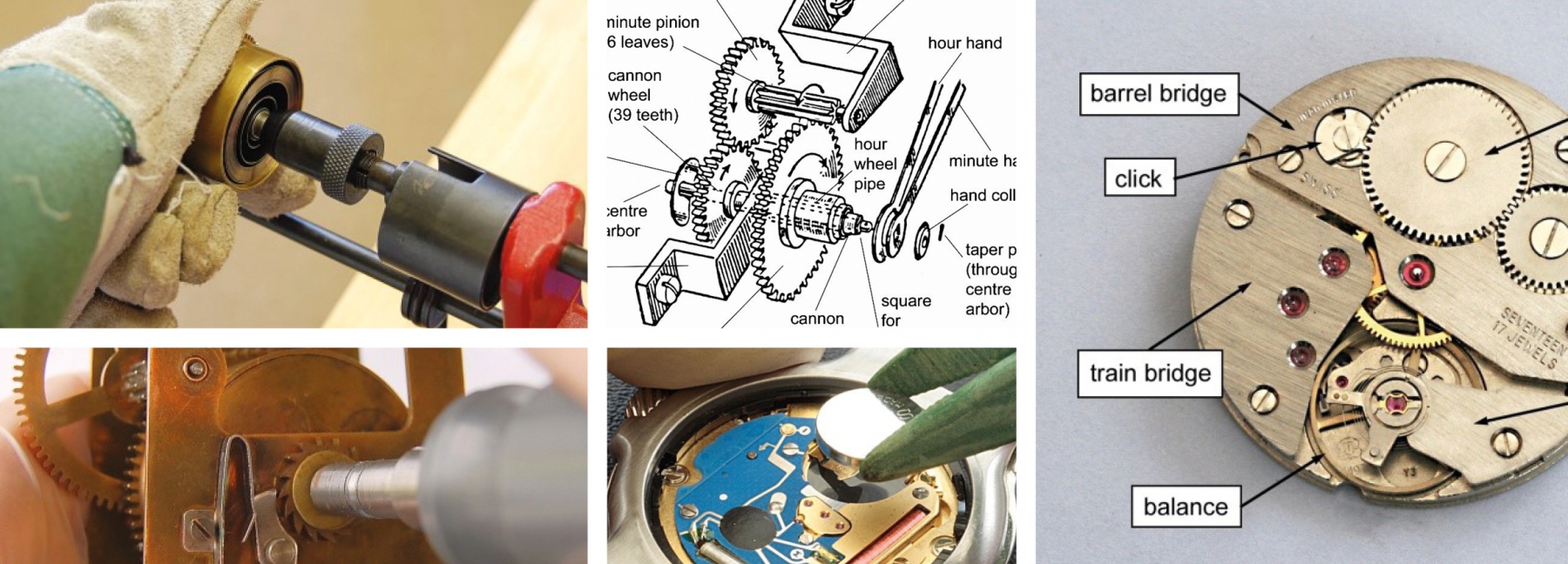

“What I learned from my grandfather is you don’t have to walk the beaten path,” said Shapiro, who grew up in Arcadia. They heated the recovered precious metal in a furnace until it coalesced, and poured it out as a nugget that Shapiro later made into a coin. Then about 6 years old, Shapiro would salvage gold that had been deposited in or on the company’s crucibles. One of the duo’s early “projects” was smelting gold. (Think: gears, wheels, levers and springs.) Shapiro has done his research, and believes Resurgence complies with strict Federal Trade Commission rules that dictate when a consumer good warrants the “U.S. made” engraved on the movement - the mechanical innards that power a traditional timepiece. The Inglewood company aims to make about 30 a year, and each watch will have “U.S. Versions in other metals, including tantalum, begin at $80,000. Resurgence, which debuted Monday, starts at $70,000 in a steel case. Shapiro Watches’ latest project is without equal in contemporary American watchmaking. “That’s when I got into this and had this wild dream of making my own watch - making every part of a watch,” he said. It’s part of a process that spanned thousands of hours and began 12 years ago. He estimated he’d spent upward of 30 hours designing and fabricating this piece for the watch, a prototype of Resurgence.

#Horology courses how to

know how to do it.Īfter honing the pattern - and some hand wringing over just how wavy it should be - Shapiro would make the final part in sterling silver. Only a handful of watchmakers in the U.S. This decorative technique is know as guilloché, which was invented in the 1500s and also is known as engine turning. On this day, he was adorning the German silver - a fancy name for nickel - with moiré, a wavy motif occasionally seen on high-end watches. something that hasn’t been done in a half century or so. Shapiro’s watch would be almost fully made in the U.S. He hoped the timepiece, called Resurgence, would revive a once-great American industry. Shapiro, 38, was practicing the pattern that would decorate part of the dial on his new watch. And shards of the silvery material were ejected from the plate where the machine’s cutter made contact. Standing at the helm of the 100-year-old “rose engine,” he peered through a microscope at a small, square slab of German silver illuminated by a gooseneck lamp. Watchmaker Joshua Shapiro gripped the machine’s worn handle with his left hand and exhaled.

0 kommentar(er)

0 kommentar(er)